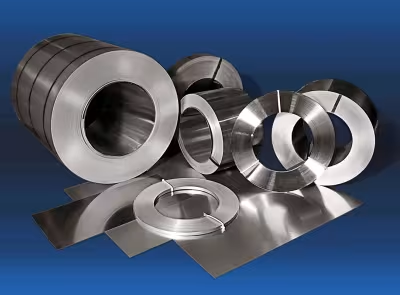

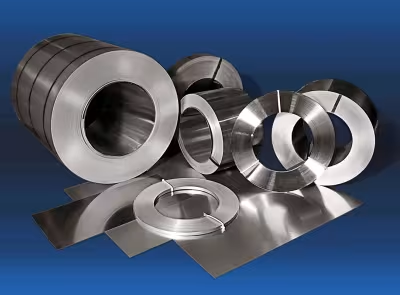

17-7PH Stainless Steel Sheet, Plate & Coil - AMS 5528, UNS S17700

17-7 PH is a precipitation-hardened stainless steel that is well suited for aerospace and other applications requiring high strength and good corrosion resistance and formability. Type 17-7 PH is a Chromium-Nickel-Aluminum, austenitic stainless steel. It is the most formable of all PH grades and has the highest strength and hardness. It is less magnetic than other PH grades and offers minimal distortion upon heat treatment. This material maintains its valuable properties at temperatures up to 800°F (427° C).

Inventory Size Ranges for 17-7 PH

| Type |

Thickness |

AMS Standards | ASTM | UNS | ASME | Get a Quote |

| Coil |

0.020" - 0.125" |

AMS 5528 | ASTM A 693 | UNS S17700 | ASME SA 693 |

Get a Quote

|

| Sheet |

0.020" - 0.125" |

AMS 5528 | ASTM A 693 | UNS S17700 | ASME SA 693 |

Get a Quote

|

| Plate |

0.1875" |

AMS 5528 | ASTM A 693 | UNS S17700 | ASME SA 693 |

Get a Quote

|

Not finding what you are looking for? Connect with our specialty metals sourcing group.

Characteristics of 17-7

Provides benefits for applications requiring high strength and good corrosion resistance. This material also maintains hardness and has excellent fatigue properties.

Other industry standards we comply with:

- W.NR 1.4541

- PWA-LCS

- GE Aircraft Engine (GT193)

- GE Aviation S-SPEC-35 AeDMS S-400

- RR SABRe Edition 2

- DFARS Compliant

Common Trade Names

- 17-7 (® AK Steel)

- ATI 17-7 (™ Allegheny Technologies)

- T-17-7 Stainless Steel (ThyssenKrupp VDM)

Industry Applications for 17-7 PH

- Aerospace applications

- Chemical processing equipment

- Oil and petroleum refining equipment

- Food grade stainless steel for processing equipment

- General metalworking

Chemical Composition

Chemical Composition Percentage of 17-7 PH

|

Element |

Min |

Max |

| C |

Carbon |

- |

0.09 |

| Mn |

Manganese |

- |

1.00 |

| P |

Phosphorus |

- |

0.05 |

| S |

Sulfur |

- |

0.03 |

| Si |

Silicon |

- |

1.00 |

| Cr |

Chromium |

16.00 |

18.00 |

| Ni |

Nickel |

6.75 |

7.75 |

| Al |

Aluminum |

0.75 |

1.50 |

Physical Properties

- Density: 0.2820 lb/in3

- Melting Range: 2560 - 2625°F (1404 - 1440°C)

- Electrical Resistivity (Annealed Condition): 80 Microhm-cm

Linear Coefficient of Thermal Expansion| Temperature Range | Coefficients |

|---|

| °C | °F | μm/m°C | in/in/°F·106 |

|---|

| 21-93 | 70-200 | 15.3 | 8.5 |

| 21-204 | 70-400 | 16.2 | 9.0 |

| 21-316 | 70-600 | 17.1 | 9.5 |

| 21-427 | 70-800 | 17.3 | 9.6 |

Thermal Conductivity (TH 1050 Condition)| Temperature Range | Coefficients |

|---|

| °C | °F | W/m·K | Btu/(hr/ft²/in/°F) |

|---|

| 149 | 300 | 16.87 | 117 |

| 260 | 500 | 18.46 | 128 |

| 449 | 840 | 21.05 | 146 |

| 482 | 900 | 21.05 | 146 |

Magnetic Permeability (Annealed Condition)| Oersteds | AT/m | μ |

|---|

| 25 | 1989 | 1.4 - 3.4 |

| 50 | 3878 | 1.4 - 3.6 |

| 100 | 7956 | 1.4 - 3.5 |

| 200 | 15.912 | 1.4 - 3.2 |

| max | max | 1.4 - 3.6 |

Mechanical Properties

Mechanical Properties and Yield Strength at Room Temperatures (Annealed)

- Ultimate Tensile Strength psi (MPa): 130,000 (896)

- 0.2% Tensile Yield Strength psi (MPa): 40,000 (276)

- Elongation % in 2" (50mm): 35

- Hardness Rockwell: B85

Additional Info